Industrial wireless systems research

The US National Institute of Standards and Technology (NIST) is developing best-practice guidelines for evaluating and integrating wireless technologies into modern factories.

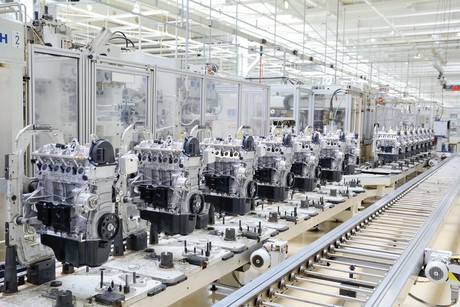

Providing wireless communications in a factory, plant or other industrial environment these days means more than just helping employees talk with each other while they work. By eliminating physical connections such as wires and cables from a facility’s communication network, wireless technology offers many manufacturing, chemical processing and municipal (such as water treatment) organisations a means to run their entire operation more efficiently, more productively and at less cost.

However, a perceived lack of reliability, integrity and security has hampered the adoption and use of industrial wireless, especially when wireless communication can often be corrupted or disrupted in harsh industrial settings.

Through its Wireless Systems for Industrial Environments project, NIST is working with private-sector collaborators to overcome these obstacles and make industrial wireless communication a more viable choice.

The latest milestone in this effort is a newly published study in which rigorous scientific experiments evaluated how well RF signals propagated in three different factory environments: a car transmission assembly facility, a steam generation plant and a machine shop.

“Understanding how RF platforms work or don’t work in these harsh environments is the first step toward designing and deploying reliable wireless networks,” said NIST’s Rick Candell, the lead researcher on the study.

“With the data from this research and future tests, we can define factors that can hinder RF propagation — including heat, vibration, reflection, interference and shielding — and then develop measures to address them.”

In their study of the three factory settings, Candell and his colleagues looked at three RF propagation characteristics. They made precise measurements of how the signals lost power over distance, dispersed over the factory floor and varied in strength due to absorption or reflection by the specific environment.

“We clearly saw that wireless transmission of data in industrial facilities is completely different from signal propagation in a home or office setting,” Candell said.

“It’s a harsh environment where reflective or absorbent surfaces, interference from competing RF signal traffic and other obstacles must be overcome if we want to deploy secure, integrated wireless platforms that perform dependably.”

The researchers performed mathematical and statistical analyses of the data from the three factory experiments and are incorporating them into a NIST test bed designed to replicate a manufacturing environment. This ‘factory in a box’ recreates the conditions found in a variety of industrial settings, allowing researchers to study the impacts on signal propagation in controlled laboratory conditions.

“The test bed supports the development of measurements and tests to evaluate signal performance, gives us the means to evaluate the usefulness of NIST computer models and simulations of wireless networks and, hopefully, will help us design and road test solutions to current propagation problems,” Candell said.

The NIST team also wants to hear from people involved with factories and plants about their specific industrial environments, including details about layout, structural make-up, operations and communications networking, as well as future needs and plans for wireless.

“We hope that more managers will consider letting us conduct field trials of wireless in their facilities, especially ones with outdoor operations such as oil refineries or with possible signal-absorbing materials such as paper mills,” Candell said.

***************

The Wireless Systems for Industrial Environments project

Reliable and secure real-time performance of wireless platforms in manufacturing environments is a challenging problem faced by manufacturers who choose wireless platforms to replace wired platforms due to their ease of installation, maintenance and reconfigurability. Wireless technology creates enormous potential for manufacturers by increasing the monitoring and control surface of their physical processes.

But this potentiation for fine resolution monitoring and control also brings with it technical challenges. These challenges include the impact of the unreliable wireless environment on the ability to monitor the processes and adapt quickly. Where wireless is used for control, security, safety and reliability become chief concerns. Current wireless technologies employed include IEEE 802.11, IEEE 802.15.4 and some proprietary protocols.

The key objective for the Wireless Systems for Industrial Environments project is to develop best-practice guidelines for evaluating and integrating wireless technologies into modern factories. The guidelines will include methodology and protocols that will enable, assess and assure real-time performance of secure wireless platforms in ‘smart manufacturing’ systems. These guidelines will enable manufacturers, technology providers and solution providers to design, deploy and assess robust, secure integrated wireless platforms.

Manufacturers using wireless platforms from various providers will benefit from a standardised measurement methodology and security guidelines because they can be assured that the wireless platforms for their applications will achieve the desired performance requirements and efficiency.

2025–26 Thought Leaders: Tim Karamitos

Tim Karamitos from Ericsson discusses the connectivity requirements of emergency services and...

2025–26 Thought Leaders: Ruth Tovo

Comms Connect panellist Ruth Tovo, from the South Australian SES, discusses the technical...

ARCIA update: celebrating excellence in our industry

The ARCIA Annual Gala Dinner and Excellence Awards took place during the same week as Comms...