Transforming mining with 5G connectivity

By Ian Ross, Head of Private Cellular Networks ANZ for Enterprise Wireless Solutions at Ericsson

Thursday, 09 January, 2025

The mining industry has long been a cornerstone of Australia’s and the global economy, generating over $500 billion worldwide annually and contributing 13.6% of total GDP to Australia’s economy in 2023. However, the mining industry faces growing challenges: demands for higher productivity, stringent safety and environmental management regulations, and cost pressures.

While the industry tends to be fairly conservative when it comes to adopting new technologies, several forces are working to accelerate innovation:

- Safety imperatives: Modern technologies reduce workplace hazards for works and help towards the safe management of the environment, a critical need in an industry historically fraught with risks.

- Cost and sustainability pressures: With Australia having committed to reduce the impacts of climate change and reaching net zero emissions by 2050, regulatory demands and environmental concerns are push mining firms to find solutions that help reduce emissions and improve efficiency.

- Productivity demands: Autonomous and remotely controlled equipment offers mining companies a clear return on investment. Connected assets can streamline operations, boosting output from existing mines.

The case for 5G networks

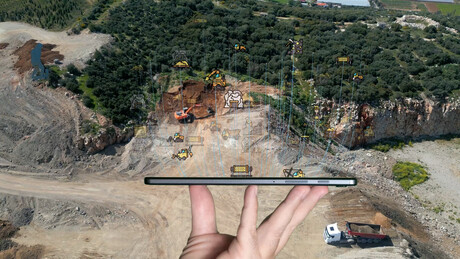

The concept of the smart mine is transforming the mining landscape, leveraging data, automation and advanced technologies to achieve unprecedented efficiencies. Ericsson’s private 5G networks deliver a robust platform for smart mines, tailored for the industry’s unique requirements. Unlike Wi-Fi or older communication technologies, private 5G offers high bandwidth, ultralow latency, and end-to-end security with a lower cost of infrastructure per km2 and deterministic capability to allow critical and non-critical applications to share the one network at the same time. At the heart of this revolution lies ubiquitous mobile connectivity. These networks enable a wide range of applications critical to smart mining:

- Autonomous vehicles: Seamlessly operate loaders, haulers, drill rigs and other machinery with precision.

- Connected workers: Enhance safety and productivity with smart wearables and real-time access to data for decision-making.

- Predictive maintenance: Use IoT sensors to feed digital twins and AI to anticipate equipment failures, reducing downtime.

- Environmental monitoring: Track emissions and minimise ecological impact in real time.

Real-world success stories

Several mining leaders globally are leveraging 4G connectivity ecosystems today, making them ready for the 5G-demand applications of the future:

- Boliden Aitik Mine (Sweden): By automating drill rig operations, the mine achieved a significant cost reduction, with plans for the rollout of fully automated, remote-controlled trucks for smoother transport flow and lowering emissions.

- Newmont Mining (Australia and Papua New Guinea): Private LTE and 5G networks empower digital transformation, allow effective use of remote-control technologies and improve operational efficiency and safety.

The Mining 4.0 opportunity

Ericsson’s private networks lay the foundation for Mining 4.0 — a new era defined by automation, sustainability and enhanced productivity. For a fully autonomous, remotely controlled smart mine, high-performance communications are needed.

When it comes to underground mines, a secure, flexible and futureproof private 5G network is essential to ensure that mine controllers can utilise their fleets where and when needed without concern for capacity and reliability. Worker locations and safety can be monitored from the surface, and arrays of sensors can be used to allow geotechnical and seismic monitoring of drives through digital twins without placing engineers in harm’s way. Another big benefit is that 5G can be deployed using lower frequency options than the equivalent Wi-Fi and a range of distribution technologies can provide both a low price per km covered, as well as potential for much higher, deterministic data rates than other technology options. For open-pit mining, private cellular networks provide strong coverage, high throughput and low latency over extended distances to connect fleets, enable improved remote control, or facilitate greater use of autonomous and semi-autonomous mining machines. Private networks also benefit open-pit mines with a suite of connected devices such as smart PPE, data loggers, AR/VR wearables, computer vision, geotechnical monitors and process control systems.

A call to action for mining executives

Like power and water, pervasive and dependable wireless connectivity is now an essential utility in mining. Mining executives must prioritise connectivity as the linchpin of their digital transformation, productivity improvement and workplace safety strategies. Private 5G solutions should not just be about technology — they should be about creating safer, more sustainable and financially viable mining operations that can be easily maintained and operated with existing technology teams.

The road to the smart mine is clear. It’s time to move beyond the challenges of today and embrace the technologies that will define the future of mining.

Canberra celebrates 60-year NASA collaboration with new dish

NASA's Deep Space Network facility in Canberra celebrated its 60th anniversary on 19 March...

ACMA releases views on future use of public airwaves

According to ACMA Deputy Chair Adam Suckling, the agency seeks to ensure the greatest benefit to...

New technique to eliminate signals disrupting radio telescopes

An unexpected television signal traced to an aeroplane has led to a new method for pinpointing...